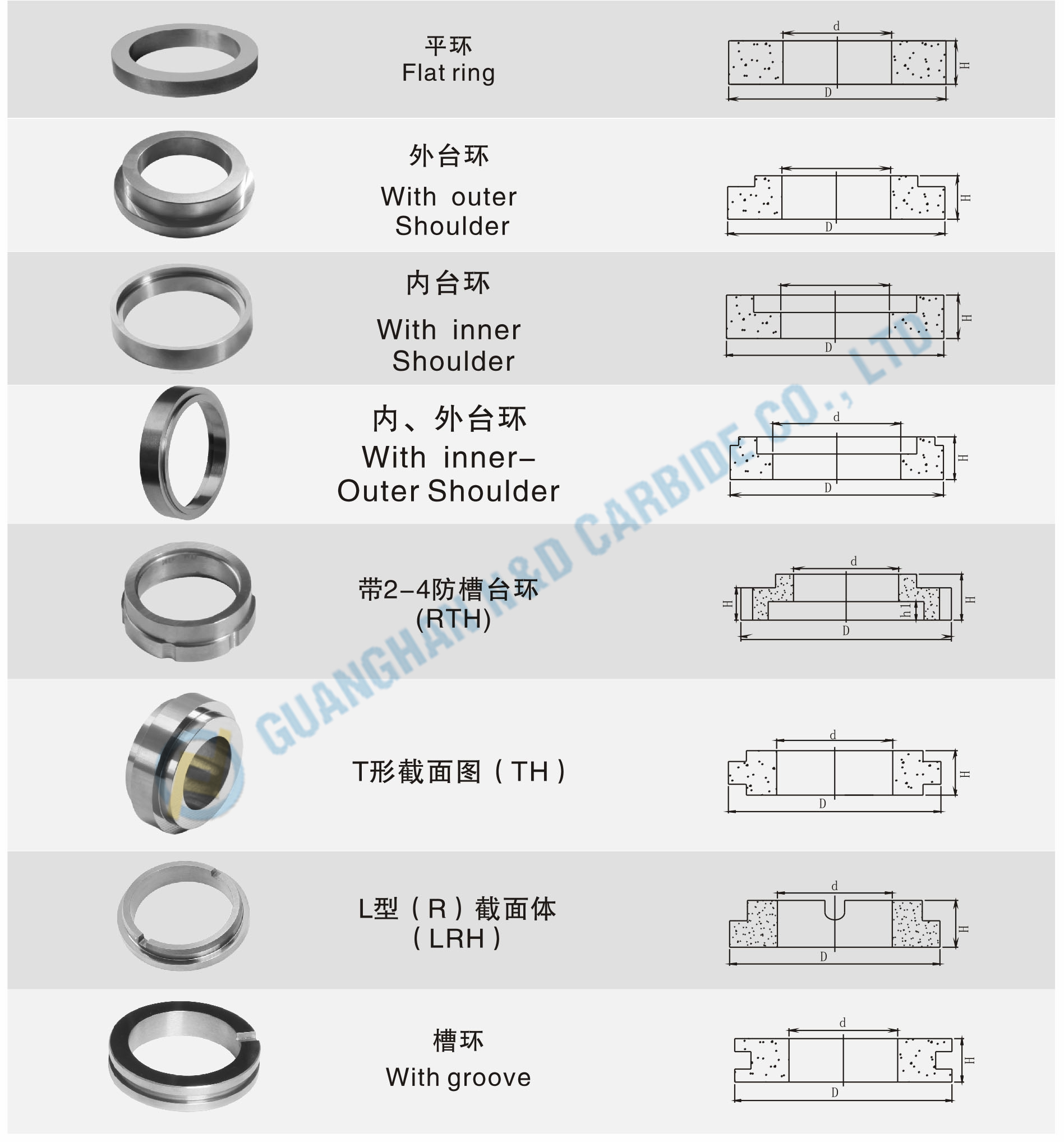

Indandatho yesiTywina seTungsten Carbide esenziwe ngokwezifiso kwiiMpawu zoMatshini

Inkcazo emfutshane:

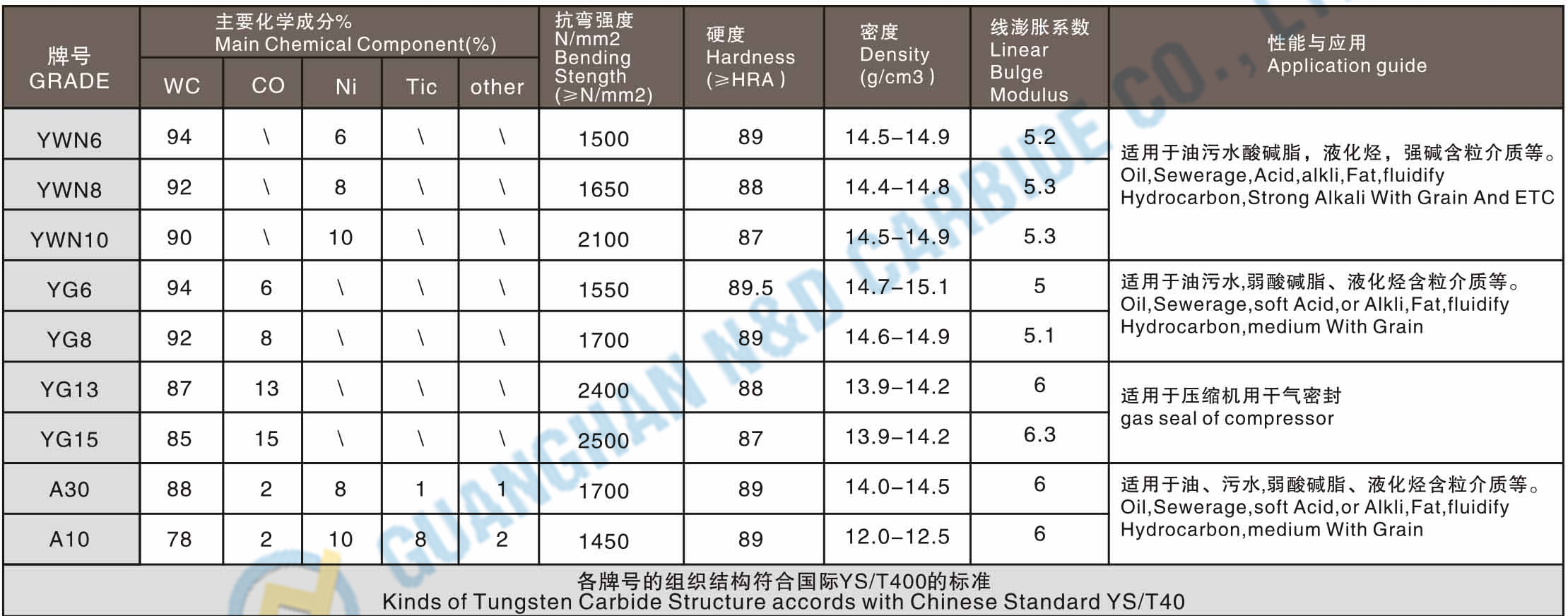

* I-Tungsten Carbide, i-Nickel/Cobalt Binder

* Izithando zeSinter-HIP

* Umatshini we-CNC

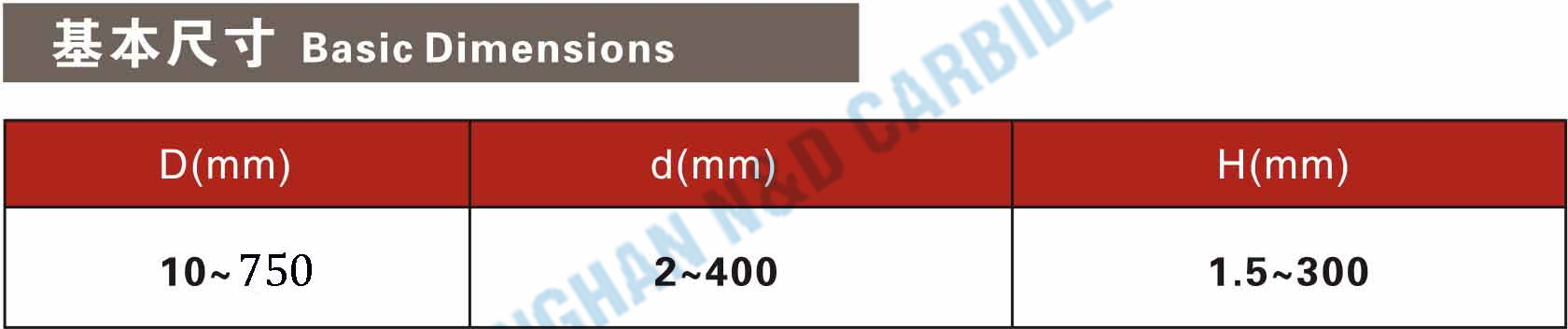

* Ububanzi bangaphandle: 10-800mm

* I-Sintered, igqityiwe umgangatho, kunye ne-mirror lapping;

* Ubungakanani obongezelelweyo, ukunyamezelana, amabakala kunye nobungakanani ziyafumaneka xa ziceliwe.

Ukwazisa iRingi yethu yesitywino seTungsten Carbide eyenzelwe wena, isisombululo sokugqibela sokuqinisekisa ukusebenza kakuhle kunye nobude bexesha kwiisetingi zoomatshini. Zenziwe ngokuchanekileyo nangobuchule, iiringi zethu zesitywino zenzelwe ukumelana neemeko zoshishino ezifuna kakhulu, zibonelela ngokumelana nokuguguleka okugqwesileyo kunye nokuthembeka.

Iiringi zethu zeTungsten Carbide Seal Rings zenziwe ngokwezifiso ukuhlangabezana neemfuno ezithile zeeringi zoomatshini, ukuqinisekisa ukulingana okugqibeleleyo kunye nokuhlanganiswa okungenamthungo. Ubunzima obuphezulu kunye nokuqina kwe-tungsten carbide kuyenza ibe yinto efanelekileyo kwiiringi zeseal, ibonelela ngokumelana okuhle nokukrala, ukugqwala, kunye nobushushu obuphezulu. Oku kuthetha ukuba iiringi zethu zeseal zinokuthintela ngokufanelekileyo ukuvuza kwaye zigcine itywina eliqinileyo nakwiimeko ezinzima kakhulu, ekugqibeleni zinciphise iindleko zokulungisa kunye nexesha lokungasebenzi.

Ngokuzibophelela kwethu kumgangatho kunye nokuvelisa izinto ezintsha, sisebenzisa iindlela eziphambili zokwenza imveliso ukuvelisa amaringi okuvala adlula imigangatho yoshishino. Iringi nganye ihlolwa ngononophelo ukuqinisekisa ukuchaneka kunye nokuhambelana, ukuqinisekisa ukuba abathengi bethu bafumana imveliso yodidi oluphezulu.

Ukongeza ekusebenzeni kwazo okugqwesileyo, iiRingi zethu zeTungsten Carbide Seal Rings zethu ezenziwe ngokwezifiso nazo zinokwenziwa ngokwezifiso kakhulu, zivumela izisombululo ezenzelwe wena ukuhlangabezana neemfuno ezithile zesicelo. Nokuba bubungakanani obahlukileyo, imilo, okanye iimfuno zokugquma ezikhethekileyo, sinokukwazi ukubonelela ngeeringi zeseal ezenzelwe wena ezihambelana ngokugqibeleleyo neenkcukacha zabathengi bethu.

Ngaphezu koko, ukuzinikela kwethu ekwanelisekeni kwabathengi kudlulela ngaphaya kwemveliso ngokwayo. Sinikezela ngenkxaso epheleleyo kunye nobuchule bobuchwephesha ukunceda abathengi bethu ekukhetheni indandatho yokutywina efanelekileyo kwizicelo zabo, kunye nokubonelela ngesikhokelo malunga neendlela ezilungileyo zokufakela kunye nokugcina.

Ukuqukumbela, iiRingi zethu zeTungsten Carbide Seal zeeMechanical Seals zethu zibonelela ngokuqina okungenakuthelekiswa nanto, ukuthembeka, kunye neendlela zokwenza ngokwezifiso, nto leyo ezenza zibe lolona khetho lufanelekileyo kumashishini apho izisombululo zokutywina ezithembekileyo zibaluleke kakhulu. Thembela kubuchule bethu namava ethu ukuze unikezele ngeeringi zokutywina ezihlala ziphumelela ngaphezu kolindelo kwaye zinegalelo ekusebenzeni kakuhle kweenkqubo zoomatshini.

I-Tungsten carbide (TC) isetyenziswa kakhulu njengee-seal faces okanye ii-rings ezinxitywayo, amandla aphezulu okuqhekeka, i-thermal conductivity ephezulu, kunye nokwandiswa kobushushu okuncinci okusebenza kakuhle. I-tungsten carbide seal-ring inokwahlulwa ibe yi-seal-ring ejikelezayo kunye ne-static seal-ring. Iindidi ezimbini eziqhelekileyo ze-tungsten carbide seal faces/ring yi-cobalt binder kunye ne-nickel binder.

Izitywino ze-tungsten carbide mechanical zisetyenziswa kakhulu kwipompo yolwelo ukuze zithathe indawo ye-packed gland kunye ne-lip seal. Itywino le-tungsten carbide mechanical seal Ipompo enetywino le-mechanical isebenza kakuhle kwaye ngokubanzi isebenza ngokuthembekileyo ixesha elide.

Ngokwemilo, ezo zitywino zikwabizwa ngokuba ziingcingo zokuvala ze-tungsten carbide mechanical seal. Ngenxa yobuhle bezinto ze-tungsten carbide, ii-tungsten carbide mechanical seal rings zibonisa ubunzima obukhulu, kwaye okubaluleke kakhulu kukuba ziyamelana nokugqwala nokukrala kakuhle. Ke ngoko, ii-tungsten carbide mechanical seal rings zisetyenziswa kakhulu kunezinye izinto.

I-tungsten carbide mechanical seal inikezelwa ukuthintela ulwelo olupompelweyo ukuba lungaphumi ecaleni kwe-drive shaft. Indlela yokuvuza elawulwayo iphakathi kweendawo ezimbini ezithe tyaba ezinxulumene ne-shaft ejikelezayo kunye ne-housing ngokulandelanayo. Umsantsa wendlela yokuvuza uyahluka njengoko ubuso buphantsi komthwalo wangaphandle owahlukeneyo odla ngokushukumisa ubuso obunye.

Iimveliso zifuna uyilo olwahlukileyo lwendlu yeshafti xa kuthelekiswa nolo lolunye uhlobo lwetywina loomatshini kuba itywina loomatshini lilungiselelo eliyinkimbinkimbi ngakumbi kwaye itywina loomatshini aliboneleli ngenkxaso kwishafti.

Amakhonkco okutywina oomatshini be-tungsten carbide afumaneka kwiindidi ezimbini eziphambili:

Ukubotshwa kweCobalt (ukusetyenziswa kwe-ammonia kufuneka kuphetshwe)

I-Nickel bound (Ingasetyenziswa kwi-Ammonia)

Ngokwesiqhelo izinto zokubopha ezizi-6% zisetyenziswa kwizangqa zokuvala ze-tungsten carbide mechanical seal, nangona kukho uluhlu olubanzi olufumanekayo. Iizangqa zokuvala ze-tungsten carbide mechanical seal ezibotshelelwe yi-nickel zixhaphake kakhulu kwimarike yempompo yamanzi amdaka ngenxa yokumelana kwazo nokugqwala okuphuculweyo xa kuthelekiswa nezinto ezibotshelelwe yi-cobalt.

Iiringi zeTungsten Carbide seal zisetyenziswa kakhulu njengee-seal faces kwii-mechanical seals zeepompo, ii-compressors mixers kunye nee-agitators ezifumaneka kwiindawo zokucoca ioyile, kwizityalo zepetrochemical, kwizityalo zezichumiso, kwimizi-mveliso yotywala, kwimigodi, kwii-pulp mills, nakwishishini lamayeza. I-seal-ring iya kufakwa emzimbeni wepompo kunye ne-axle ejikelezayo, kwaye yenze i-liquid okanye i-gas seal engaphaya kwe-rotation ne-static ring.

Iiringi zokutywina ze-tungsten carbide, njengemveliso ye-alloy eyenziwe ngeenkqubo ze-powder metallurgy, zinoluhlu olubanzi nolubalulekileyo lwezicelo. Apha ngezantsi kukho inkcazo eneenkcukacha malunga nobubanzi bezicelo zazo:

Imizi-mveliso ye-oyile kunye neekhemikhali

Kwimizi-mveliso yokukhupha ioyile kunye neekhemikhali, iiringi zokuvala iikhabhide zithandwa kakhulu ngenxa yokumelana kwazo nokuguguleka okumangalisayo, ukumelana nokugqwala, kunye nokumelana nempembelelo. Ezi mpawu zibenza bakwazi ukusebenza ngokuzinzileyo ixesha elide kwiindawo zokusebenza ezinzima, bethintela ngokufanelekileyo ukuvuza okuphakathi kunye nokuqinisekisa ukhuseleko lwemveliso. Iiringi zokuvala iikhabhide zihlala zisetyenziswa njengezinto ezibalulekileyo zokuvala kwiimpompo ezahlukeneyo, iicompressor, iivalvu, kunye nezinye izixhobo.

Icandelo Lokuvelisa Oomatshini

Iiringi zokutywina iikhabhide nazo zidlala indima ebalulekileyo kwicandelo lokwenziwa koomatshini. Zisetyenziswa kakhulu kwizikhokelo zeesilinda yeoyile, oomatshini abahlukeneyo bokuvelisa, kunye nezixhobo zoomatshini ezizenzekelayo, ezifana nezitywino zezinto ezitheleskopu, ezijikelezayo, ezityibilikayo, ezigobayo, nezijikelezayo. Ubunzima obuphezulu kunye nokumelana nokuguguleka kweeringi zokutywina iikhabhide kwandisa kakhulu ubomi bezixhobo, kunciphisa ukugcinwa kunye nokutshintshwa rhoqo, kwaye kunciphisa iindleko zokusebenza kumashishini.

Ishishini lezoThutho

Iiringi zokuvala iikhabhide zinendawo ebalulekileyo kushishino lothutho. Zikho kwiimoto, kwiibhayisekile, nakwiimashini ezahlukeneyo zokuphatha kunye nezolimo, apho iindawo ezininzi ezityibilikayo nezijikelezayo zifuna iiringi ezithembekileyo. Ukusebenza kokutywina kwezi nxalenye kuchaphazela ngokuthe ngqo ukhuseleko kunye nokuthembeka kwezithuthi. Iiringi zokuvala iikhabhide, kunye nokusebenza kwazo okugqwesileyo kokutywina kunye nokumelana nokuguguleka, zibonelela ngokhuseleko oluthembekileyo kwezi nxalenye.

Ishishini lezixhobo

Iiringi zokutywina iikhabhide nazo zidlala indima ebalulekileyo kushishino lwezixhobo. Njengoko izixhobo zihlala zisebenza kwiindawo ezichanekileyo nezizinzileyo, iimfuno zezinto zokutywina ziphezulu kakhulu. Iiringi zokutywina iikhabhide, ngobuchule bazo obuphezulu, ukumelana nokugqwala, kunye nokumelana nokuguguleka, zizalisekisa iimfuno ezingqongqo zezixhobo zezinto zokutywina.

Ezinye iiSithili

Ngaphezu koko, iiringi zokuvala iikhabhide zisetyenziswa kakhulu kumacandelo ahlukeneyo afana namandla, isinyithi, kunye nokulungiswa kokutya. Kwishishini lamandla, zisetyenziselwa izixhobo zokuvala xa kusenziwa umbane; kwisinyithi, zisetyenziselwa ukuvala phantsi kweemeko zobushushu obuphezulu kunye noxinzelelo oluphezulu; kwaye ekulungisweni kokutya, ukumelana kwazo nokugqwala kunye neempawu zococeko zenza zibe zizinto ezibalulekileyo kwimigca yemveliso yokutya.

Ngamafutshane, iiringi zokuvala iikhabhathi, kunye nokusebenza kwazo okuphezulu kunye noluhlu olubanzi lwezicelo, zidlala indima ebalulekileyo kumashishini anamhlanje. Njengoko ubuchwepheshe buqhubeka buhambela phambili kwaye izicelo ziqhubeka nokukhula, amathuba emarike eeringi zokuvala iikhabhathi aya kuba nethemba ngakumbi.

Kukho ukhetho olukhulu lobukhulu kunye neentlobo zendandatho yesitywina esithe tyaba se-tungsten carbide, singacebisa, siyile, siyiphuhlise, sivelise iimveliso ngokwemizobo kunye neemfuno zabathengi.

I-Guanghan ND Carbide ivelisa iintlobo ngeentlobo ze-tungsten carbide ezimelana nokugqwala kunye nokungagugi.

izinto ezisetyenzisiweyo.

*Izangqa zokutywina zoomatshini

*Iibhotshi, Imikhono

*Ii-Tungsten Carbide Nozzles

*Ibhola ye-API kunye neSihlalo

*Isiqu seChoke, Isihlalo, Iikheji, Idiski, Ukusika kweFlow..

*Iibhari zeTungsten Carbide/Iintonga/Iipleyiti/Iziqwenga

*Ezinye iindawo zokunxiba ze-tungsten carbide ezenziwe ngokwezifiso

-- ...

Sinikezela ngoluhlu olupheleleyo lweeklasi ze-carbide kwi-cobalt kunye ne-nickel binders.

Siphatha zonke iinkqubo ekhaya silandela imizobo yabathengi bethu kunye neenkcukacha zezinto eziphathekayo. Nokuba awuboni

dwelisa apha, ukuba uneengcinga esiza kuzivelisa.

Q: Ngaba urhweba ngenkampani okanye umenzi?

A: Singabenzi be-tungsten carbide ukusukela ngo-2004. Singabonelela ngeetoni ezingama-20 zemveliso ye-tungsten carbide nganye

inyanga. Singakubonelela ngeemveliso zekhabhayithi ezenzelwe wena ngokweemfuno zakho.

Q: Lingakanani ixesha lakho lokuhambisa?

A: Ngokubanzi kuya kuthatha iintsuku ezisi-7 ukuya kwezingama-25 emva kokuba i-odolo iqinisekisiwe. Ixesha elithile lokuhambisa lixhomekeke kwimveliso ethile.

kunye nobungakanani obubudingayo.

Q: Ngaba niyazibonelela iisampulu? Ngaba zisimahla okanye ziyahlawuliswa?

A: Ewe, singabonelela ngesampulu simahla kodwa imithwalo ithengiswa ngexabiso labathengi.

Q. Ngaba uyazivavanya zonke iimpahla zakho ngaphambi kokuba uzithumele?

A: Ewe, siza kwenza uvavanyo olupheleleyo novavanyo kwiimveliso zethu zekhabhayithi ezifakwe isamente ngaphambi kokuba siziswe.

1. IXABISO LEFEKTRI ;

2. Ukuvelisa iimveliso ze-carbide ezigxile kwiminyaka eli-17 ;

3.lSO kunye ne-AP| umenzi oqinisekisiweyo;

4. Inkonzo eyenzelwe wena;

5. Umgangatho omhle kunye nokuhanjiswa okukhawulezayo ;

6. Ukutshisa isithando somlilo se-HLP ;

7. Umatshini wokugaya i-CNC ;

8. Umboneleli wenkampani yeFortune 500.